34_

AC TECH >

FACTORY

Mattia Gasparin AC

Production Manager

AC

A

The technological evolution of the industrial phases of production and testing is correlated to the

gradual and continual path towards bringing the product to perfection, a process which Antonio

Carraro is a master of in its particular sector. The path of product development is the driving force

that allows us to keep our position as market leader. The commitment and dedication that the R&D

Department (Research & Development) invests into product development, the constant push towards

reaching perfection in AC tractors, has contributed to the development of a family of tractors that can

be modified and therefore significantly evolve the concept of the final test being carried out on the

production lines.

The team dedicated to the production line controls, made

up of Quality, Industrialisation and Assembly, has taken

full advantage of the opportunity given to them by R&D

and has developed a system of pre-varnish

tests that

allow the working of the tractor

to be checked before

it is completed, regardless of the control phases being

distributed throughout the assembly process, in order

to intercept any remaining anomalies. Now, thanks to

substantial conceptual modifications to the AC tractors, it

has been possible to carry out this operation prior to the

varnishing of the chassis, at the end of the transmission

assembly line, therefore after having assembled the rear

gearbox, central tunnel, axle, engine and hydraulic system.

The chance to test the transmission and its torque and PTO

power, thanks to a special testing bench, is the defining

element which separates the process fromwhat was done

previously, in that before, this activity was carried out at

the final stage of testing.

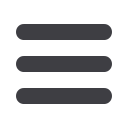

Therefore, when the tractor chassis comes off the transmission assembly line and enters the power testing bench area, the final test employee, behind the bench,

carries out preparatory and safety operations in order to be able to carry out other tests (from connecting refrigeration liquid to the engine, to hydraulic and

electrical connections). Once the preparatory phase has been completed, the employee comes out from behind the bench and starts the test on the appropriate

console that replicates the tractor’s dashboard and joystick. This is followed by some test phases that are carried out after the ignition of the endothermic engine:

The key to the success of the Antonio Carraro philosophy, that sets it apart from its competitors, in addition to the multi-purpose concept (with the prerogative

of being able to carry out more tasks with the same tractor) is its production organisation. During product development phases, many company departments

interact with each other to get the most out of every single new project, with the common objective of supplying the market with better performing, safer and

more reliable tractors.

Control of the hydraulic system capacity

Speed insertion test (all ranges)

Disengagement and traction block test

Electrical functioning test

Joystick functioning test (where required)

Hydraulic outlet test

Maximum pressure of each hydraulic outlet

Oil temperature

Exhaust pressure

Oil flow

Verification of min-max rpm of endothermic engine

Measurement of torque transmitted to the PTO